Taking piston out

Moderators: John@sos, charlesp, Charles uk, RickUK, Petergalileo

Taking piston out

Hi Guys, can I ask for some help again please?

I'm working on a seized engine. I've got it stripped as far as I've not taken the flywheel off, but I've got the driveshaft, exhaust, etc off. I got the gears and the driveshaft moving again, I've now taken off the crakcase cover to expose the piston rod and the piston end, boy is the piston stuck solid. What I'm not sure of is, if I take the piston rod off (ie snip the wire and unsrew the two screws on the collar at the rocker, will this give me problems when I rebuild, will I have to relign the timing at the points etc.

I've got diesel soaking on the piston from the rod end, should I just wait and see if this releases the piston without stripping anything else off?

I'm not mechanically minded regarding setting the points hence the reason I don't want to disturb things if it's going to cause me this hassle?

Any sound advice would be appreciated.

Gerard

I'm working on a seized engine. I've got it stripped as far as I've not taken the flywheel off, but I've got the driveshaft, exhaust, etc off. I got the gears and the driveshaft moving again, I've now taken off the crakcase cover to expose the piston rod and the piston end, boy is the piston stuck solid. What I'm not sure of is, if I take the piston rod off (ie snip the wire and unsrew the two screws on the collar at the rocker, will this give me problems when I rebuild, will I have to relign the timing at the points etc.

I've got diesel soaking on the piston from the rod end, should I just wait and see if this releases the piston without stripping anything else off?

I'm not mechanically minded regarding setting the points hence the reason I don't want to disturb things if it's going to cause me this hassle?

Any sound advice would be appreciated.

Gerard

Re: Taking piston out

It will be easier to work on with the con rod disconnected from the crank, doing that will not change the timing it is fixed by the large screw under the stator plate[bottom of the magneto]. The screw is registered into a dimple on the upper crankcase that the stator plate slips over.

There are two ways of proceeding; slow and patient, quick and rough. There are a few options for both paths. To illustrate here are two. Slow way continue soaking, fast way [assuming you have access to a piston, wrist pin and possibly rod] pound the piston out with a bar or rod through the spark plug hole [using an aluminium bar to avoid marring the spark plug threads]

There are other variations as well; Slow way, fill above piston completely with diesel or your favorite penetrating oil, replace spark plug tightly heat cylinder to drive the oil past the piston. This assumes the piston is above all port openings or that you have sealed off the ports, probably by using aluminium plate cut and drilled to fit and well bolted down possibly with gaskets to help make a seal. Another variation is to make up a fitting from an old spark plug [cleanout the porcelain and drill and tap for a grease fitting] screw it in after filling the cylinder with grease and try pumping the piston out.

As I see it and in my opinion, after working on quite a few different motors, some very old and valuable, the appropriate method depends on the value of the motor. If it will be easy to get new or used parts, I would have no hesitation to use the quick methods. A very old or valuable motor is a different story.

There are two ways of proceeding; slow and patient, quick and rough. There are a few options for both paths. To illustrate here are two. Slow way continue soaking, fast way [assuming you have access to a piston, wrist pin and possibly rod] pound the piston out with a bar or rod through the spark plug hole [using an aluminium bar to avoid marring the spark plug threads]

There are other variations as well; Slow way, fill above piston completely with diesel or your favorite penetrating oil, replace spark plug tightly heat cylinder to drive the oil past the piston. This assumes the piston is above all port openings or that you have sealed off the ports, probably by using aluminium plate cut and drilled to fit and well bolted down possibly with gaskets to help make a seal. Another variation is to make up a fitting from an old spark plug [cleanout the porcelain and drill and tap for a grease fitting] screw it in after filling the cylinder with grease and try pumping the piston out.

As I see it and in my opinion, after working on quite a few different motors, some very old and valuable, the appropriate method depends on the value of the motor. If it will be easy to get new or used parts, I would have no hesitation to use the quick methods. A very old or valuable motor is a different story.

Re: Taking piston out

Thanks Phil, the piston is down past the opening of the carb. Here are a load of pics, you can't see the rust deposits on the cylinder block though, so maybe soaking is my option, I will however disconnect the piston rod and give

myself more access.

myself more access.

Re: Taking piston out

It appears to me that the piston is high enough in the cylinder to use one of the methods mentioned to force the piston to move. In other words, if you were to observe the piston through the spark plug hole, it has not moved down the cylinder enough to uncover the exhaust port yet. On the power stroke the piston moves down uncovering the exhaust port first before uncovering any other ports. So it looks to me as though you are good to go.

I would completely remove the cylinder block from the crankcase to start with, it would be much easier to handle that way.

Then you could use the method of completely filling the cylinder with diesel, paraffin, kerosene or whatever can easily work its way past the piston when under pressure. Take pains to get it completely filled with zero air space [tap on the sides to release any air bubbles] putting the spark plug in should cause some overflow back up the spark plug threads before you get it completely tight. The process of filling it until the spark plug is in and well tightened should proceed without changing the position of the cylinder [spark plug facing up]. This to avoid any chance of air getting in.

Next with the cylinder lying exhaust port up, and having found cork [or other suitable material] to fit the water inlet and outlet on the block, boil some water and pour it into the waterjacket of the cylinder, plug with corks or whatever you decided to use to close off the water jacket inlet and outlet. Turn the cylinder block so the inside of the piston faces up and fill with ice and water. Go away and let the temperatures equalize. Remove spark plug tap lightly on the piston with a wooden dowel to see if it will move.

Repeat as necessary until piston starts to move.

This is the type of procedure one might use on a valuable motor that you have little or no hope of finding parts for.

If you should decide to pound the piston out, I would recommend removing the aluminum cylinder head, less chance of damaging it.

Personally I would never go to these lengths on any common Seagull, but I guess it could be a learning experience if you have lots of free time. I would just pound it out starting with a wooden dowel[if unsuccessful at first, work my way up to harder materials and bigger hammers], then aluminum rod, then remove head and and use a slightly smaller than piston sized piece of brass cylinder and however big a hammer or hydraulic press it may take or that is available to you.

You might get lucky and have it come out and still be useable or you might have to buy a used piston and possibly a con rod. If you are unlucky or less coordinated than normal, maybe a block as well. This is what parts motors are for.

I would completely remove the cylinder block from the crankcase to start with, it would be much easier to handle that way.

Then you could use the method of completely filling the cylinder with diesel, paraffin, kerosene or whatever can easily work its way past the piston when under pressure. Take pains to get it completely filled with zero air space [tap on the sides to release any air bubbles] putting the spark plug in should cause some overflow back up the spark plug threads before you get it completely tight. The process of filling it until the spark plug is in and well tightened should proceed without changing the position of the cylinder [spark plug facing up]. This to avoid any chance of air getting in.

Next with the cylinder lying exhaust port up, and having found cork [or other suitable material] to fit the water inlet and outlet on the block, boil some water and pour it into the waterjacket of the cylinder, plug with corks or whatever you decided to use to close off the water jacket inlet and outlet. Turn the cylinder block so the inside of the piston faces up and fill with ice and water. Go away and let the temperatures equalize. Remove spark plug tap lightly on the piston with a wooden dowel to see if it will move.

Repeat as necessary until piston starts to move.

This is the type of procedure one might use on a valuable motor that you have little or no hope of finding parts for.

If you should decide to pound the piston out, I would recommend removing the aluminum cylinder head, less chance of damaging it.

Personally I would never go to these lengths on any common Seagull, but I guess it could be a learning experience if you have lots of free time. I would just pound it out starting with a wooden dowel[if unsuccessful at first, work my way up to harder materials and bigger hammers], then aluminum rod, then remove head and and use a slightly smaller than piston sized piece of brass cylinder and however big a hammer or hydraulic press it may take or that is available to you.

You might get lucky and have it come out and still be useable or you might have to buy a used piston and possibly a con rod. If you are unlucky or less coordinated than normal, maybe a block as well. This is what parts motors are for.

Re: Taking piston out

Its probably worthwhile to take a propane torch and get the cylinder very hot, [try to heat it evenly to minimise possible damage to the cast iron] and let it cool. Do not cool the cylinder too quickly by quenching it in a cold fluid. Repeat several times. Find a wood dowel less than 18mm in dia. to tap the piston top between heating and cooling cycles. Sometimes the heating and cooling is enough to loosen up the piston. When it starts to move add more oil and work it back and forth until it will come out.

Re: Taking piston out

Cheers. I've now disconnected the piston rod and the whole cylinder block is now sitting in a tub of diesel, minus all the air.

What I have noticed is encrusted bits of rust on the cylinder, should the diesel help to get this off? I assume now abrasives should be used on this surface!

One thing I have been talking to another member about, when I look inside the plug port, there's a metal cover restraining me from getting a rod into the piston. I'm told this is common on FPs. I will however try tapping from the other end. Time is no problem as I have a good engine running and this is a project, so no smashing will be done.

Thanks for all the help, I'm really into this now.

Gerard

What I have noticed is encrusted bits of rust on the cylinder, should the diesel help to get this off? I assume now abrasives should be used on this surface!

One thing I have been talking to another member about, when I look inside the plug port, there's a metal cover restraining me from getting a rod into the piston. I'm told this is common on FPs. I will however try tapping from the other end. Time is no problem as I have a good engine running and this is a project, so no smashing will be done.

Thanks for all the help, I'm really into this now.

Gerard

Re: Taking piston out

Take the spark plug out of your running motor and rotate the magneto, I am certain you will find you are looking at the piston top and NOT a metal cover, [metal cover between the ali cylinder head and the piston?] Ask your friend what the part # is? I have had many of these motors apart there is no place for such a metal cover. The best place to tap on the piston is from the top on the highest part of the piston, that is strongest. There is greater risk of damage tapping on the bottom of the piston.

Re: Taking piston out

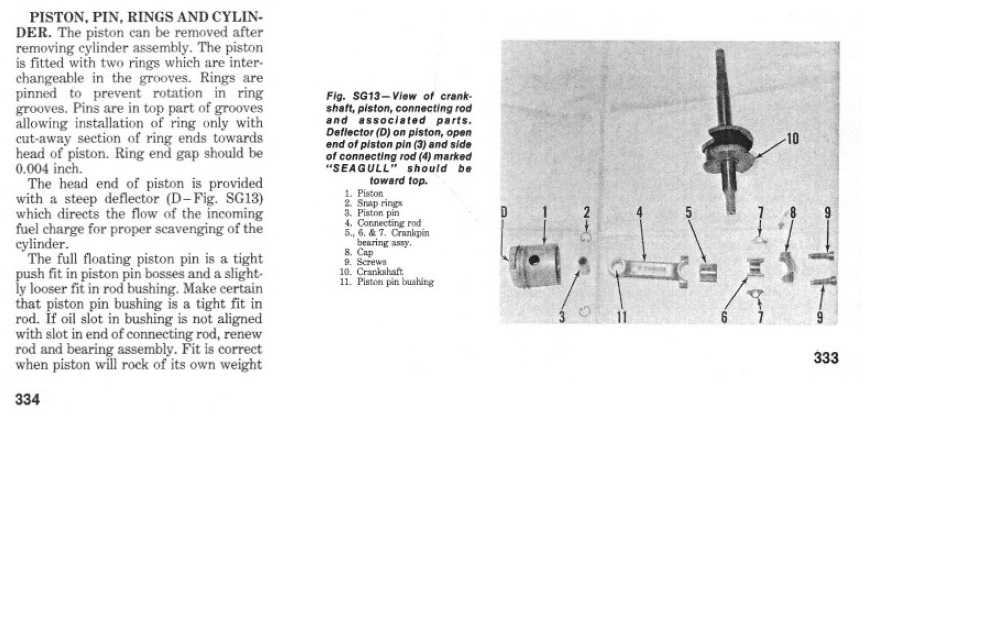

Sorry Phil, I actually was talking to one of the guys on the forum. I think it's a deflector, it's on the drawing on the page after "service sheet 3" in the manual. It doesn't cover the whole end of the piston, but most of it.

Re: Taking piston out

I humbly appologise, I just looked on the ebay pages and see the top of the piston is shaped like that. Going to Specsavers tomorrow. I will now do as you say and tap from here.

Sorry Phil, I'm too smart for my own good at times, need to listen and ask before assuming.

Sorry Phil, I'm too smart for my own good at times, need to listen and ask before assuming.

Re: Taking piston out

Hey, no problem at all. Cheers Phil

Re: Taking piston out

outboard wrote:Sorry Phil, I actually was talking to one of the guys on the forum. I think it's a deflector, it's on the drawing on the page after "service sheet 3" in the manual. It doesn't cover the whole end of the piston, but most of it.

A picture is worth...

I have no idea what the deflector is but it seems that it is fitted to the top of the piston. I would bang away. Well tap, heat, cuss, tap harder, etc.etc.

Going home after a long day

http://farm2.static.flickr.com/1415/132 ... 8754_b.jpg

The fleet at Summit. Mt. McKinley is about 45nm away at 20,320 msl.

http://farm1.static.flickr.com/187/4373 ... 2482_b.jpg

http://farm2.static.flickr.com/1415/132 ... 8754_b.jpg

The fleet at Summit. Mt. McKinley is about 45nm away at 20,320 msl.

http://farm1.static.flickr.com/187/4373 ... 2482_b.jpg

Re: Taking piston out

Cheers Pete, all this info has given me everything I need. Once I get the piston out I'm going to hone the cylinder and fit new rings. One of the other guys has given me information on doing this. I will get a hardwood dowel and given this thing one good knock.

Re: Taking piston out

Hey Pdp, How is the planning coming along for your epic trip?

Re: Taking piston out

On schedule. I have most of the spare parts I need, my SPOT beacon has a new battery, and I have been given a dry suit to use on the dicey section. I have a big piece of ash that I have yet to cut for a motor mount for the Seagull but that's the last bit of kit that I have to procure. I did have a chance to do some aerial reccon of the route and was a bit intimidated by a section of coast that has nothing but cliff at high tide, no way to get off the water. But I knew that I am going to have to be careful.Hugz wrote:Hey Pdp, How is the planning coming along for your epic trip?

The good news is that we are gaining more than 5 minutes of daylight each day as the sun is racing toward towards the northern hemisphere. (Maybe that explains some of testiness of our southern correspondents... the initial withdrawl symptoms of dimishing daylight. My attitude definitely improves when I no longer have to use the snow blower on the driveway twice a day. ) At this rate, the ice may be off the water by mid April, early May at the latest.

Going home after a long day

http://farm2.static.flickr.com/1415/132 ... 8754_b.jpg

The fleet at Summit. Mt. McKinley is about 45nm away at 20,320 msl.

http://farm1.static.flickr.com/187/4373 ... 2482_b.jpg

http://farm2.static.flickr.com/1415/132 ... 8754_b.jpg

The fleet at Summit. Mt. McKinley is about 45nm away at 20,320 msl.

http://farm1.static.flickr.com/187/4373 ... 2482_b.jpg

Re: Taking piston out

Hello Guys, it's a happy wee man here today, the piston is out. After 3 weeks of soaking in diesel I got a long roofing bolt and gave it a gentle but firm tap through the plug hole, this moved it a fraction then it took some soft gentle taps to get it out. As expected, there's signs of rust so I'm now going to get myself a three legged Glaze breaker as suggested by RBT. The piston rings look flush on the piston so I assume this is a sign of wear, hence an email to John for new rings is on the cards.

Thanks to everyone for the help so far, it's most appreciated.

As a footnote, I appologise to everyone for my posts being on two sections, the other post was not meant to get information, it was more of a picture gallery for newcomers like myself to see what a stripped engine consists of, and what to expect.

Thanks

Gerard

Thanks to everyone for the help so far, it's most appreciated.

As a footnote, I appologise to everyone for my posts being on two sections, the other post was not meant to get information, it was more of a picture gallery for newcomers like myself to see what a stripped engine consists of, and what to expect.

Thanks

Gerard