We have a Seagull Outboard

Moderators: John@sos, charlesp, Charles uk, RickUK, Petergalileo

Re: We have a Seagull Outboard

Nice to see more seagulls in Derbyshire!

Re: We have a Seagull Outboard

Nice to hear from you, Oyster. They say that the village of Coton in the Elms , Derbyshire is the furtherest point from the sea in England. Sometimes Derby itself feels like it! I've been away with work the last few days, however I hope to have another look at my Seagull before the weekend. I still haven't purchased any oil for either the fuel/oil mix or the gear box. Do you know of anywhere in Derbyshire that sells these?

I have to think about a barrel or waterbutt to run this thing in soon.

Mike

I have to think about a barrel or waterbutt to run this thing in soon.

Mike

Re: We have a Seagull Outboard

A wheelie bin is always an option.

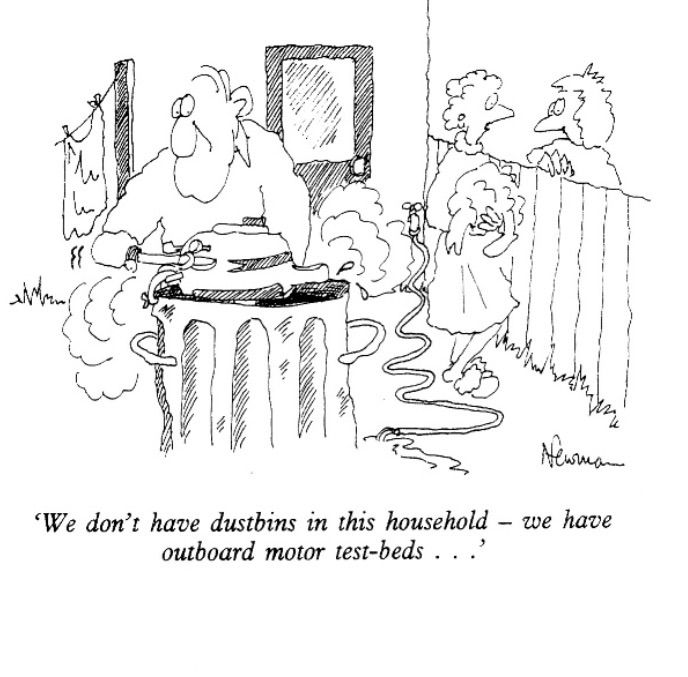

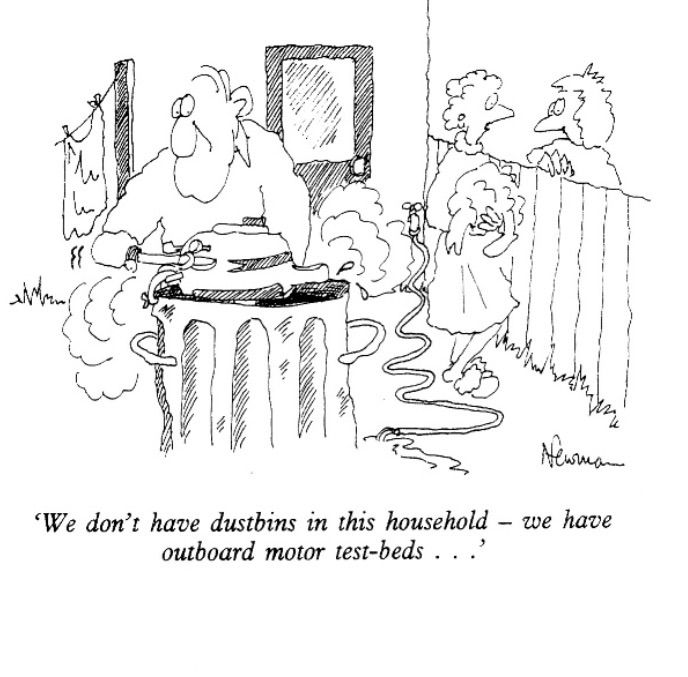

Wheelie Bin Test Bed

Keith, I had thought about using our Wheelie Bin, however I had already seen this cartoon (on the Saving Old Seagulls Forum?)

There could be critism if I'm seen using the family Wheelie Bin for 'inappropriate purposes'!

Also I'm worried about our Wheelie-Bin being too high for me - picturing myself up a stepladder to get the motor in! I guess I'm looking for something like this

50 litre bins. Shall these enable the prop shaft etc to be deep enough in the water for testing?

50 litre bins. Shall these enable the prop shaft etc to be deep enough in the water for testing?

There could be critism if I'm seen using the family Wheelie Bin for 'inappropriate purposes'!

Also I'm worried about our Wheelie-Bin being too high for me - picturing myself up a stepladder to get the motor in! I guess I'm looking for something like this

50 litre bins. Shall these enable the prop shaft etc to be deep enough in the water for testing?

50 litre bins. Shall these enable the prop shaft etc to be deep enough in the water for testing?Re: We have a Seagull Outboard

They look a little short, the outboard skeg will keep the prop away from hitting the bottom of what ever you use, not the sides obviously.

Measure your outboard from skeg to thumb screws and that will give you an idea of depth, you can go shorter, but this will only make the motor more top heavy and unstable when starting.

Good old water buts. (test tanks)

Zimma frame. (outboard stand)

Measure your outboard from skeg to thumb screws and that will give you an idea of depth, you can go shorter, but this will only make the motor more top heavy and unstable when starting.

Good old water buts. (test tanks)

Zimma frame. (outboard stand)

Re: We have a Seagull Outboard

Anything is possible.

looks right to me. Too little water and the water pump will struggle, too deep and it may struggle to start, especially on older motors with low compression.

One of my motors that I have used on my boat, the water level is just below the transom bracket, so it will run deeper on the back of a boat, so no lower than the red line and you will be fine, as long as you are not using a bucket.

looks right to me. Too little water and the water pump will struggle, too deep and it may struggle to start, especially on older motors with low compression.

One of my motors that I have used on my boat, the water level is just below the transom bracket, so it will run deeper on the back of a boat, so no lower than the red line and you will be fine, as long as you are not using a bucket.

Re: We have a Seagull Outboard

Looking at my points

My photograph looks the same as photographs here. I am used to rotating an engine and seeing the points open and close. On this Seagull, that I cannot do this as the flywheel only lets lets you look through the hole at one point of the rotation. As you can see, my points are closed in this photograph. Everything looks clean and not corroded or dirty. I can put my finger in through the access hole and easily open and close the points. Inserting a screwdriver (incidentally there is quite a strong magnetic field inside - I presume this is good?) The Points Locking Screw undoes easily. When undone the Points Adjustment Screw does turn, albeit not so easily. As I turn it, I do not see the points open. Is it anti-clockwise or clockwise to open the gap?

Any suggestions would be appreciated.

Thank you, Mike.

My photograph looks the same as photographs here. I am used to rotating an engine and seeing the points open and close. On this Seagull, that I cannot do this as the flywheel only lets lets you look through the hole at one point of the rotation. As you can see, my points are closed in this photograph. Everything looks clean and not corroded or dirty. I can put my finger in through the access hole and easily open and close the points. Inserting a screwdriver (incidentally there is quite a strong magnetic field inside - I presume this is good?) The Points Locking Screw undoes easily. When undone the Points Adjustment Screw does turn, albeit not so easily. As I turn it, I do not see the points open. Is it anti-clockwise or clockwise to open the gap?

Any suggestions would be appreciated.

Thank you, Mike.

Re: We have a Seagull Outboard

Turning the flywheel clockwise or anti-clockwise it makes no odds, the cam that the points run on is the centre for the flywheel, removing the flywheel will give you better access, but you have to set the points with the flywheel on.

As you have played with the points, you will have to reset them, set the points at just open, as you are trying to find the highest point on the cam, that's when they are open, rotate the flywheel until you see the points gap either open more or close, once you find this, then you set the gap.

The points only open for a small part of the flywheel rotation, you can see it though one of the holes, go slow.

As you have played with the points, you will have to reset them, set the points at just open, as you are trying to find the highest point on the cam, that's when they are open, rotate the flywheel until you see the points gap either open more or close, once you find this, then you set the gap.

The points only open for a small part of the flywheel rotation, you can see it though one of the holes, go slow.

A barrel from a skip

I spotted a barrel in a skip. It is now in my garden.

It is 40 cm diameter and 80 cm high. I guess that makes it a 100 litre odd barrel. I still think in terms of 44 gallon drums! I shall think about making some sort of frame for it to sit in/upon and on which I can mount the Seagull engine. I liked the welded square section trolley design that appears in the photograph I borrowed earlier in this thread. If anybody has photographs of suggested, easily made test mounts, I would appreciate them being posted. Thank you. I have wooden pallets! I do not have a welder - I'd like one!

I think I have set the points to 20 thou. We shall see, I guess. I unscrewed the bowl on the bottom of the carburettor and it seemed very clean, so I screwed it back on. I did not check the small filter that Keith referred to earlier. It appears to be easily damaged.

I have to reinstall the fly-wheel and the fuel tank. I shall then reconnect the fuel line.

I have bought neither gear-box oil nor two-stroke oil yet. I was hoping that somebody might have posted a source in Derbyshire, however no luck yet. I shall probably order them online this week.

Thanks for the help here.

It is 40 cm diameter and 80 cm high. I guess that makes it a 100 litre odd barrel. I still think in terms of 44 gallon drums! I shall think about making some sort of frame for it to sit in/upon and on which I can mount the Seagull engine. I liked the welded square section trolley design that appears in the photograph I borrowed earlier in this thread. If anybody has photographs of suggested, easily made test mounts, I would appreciate them being posted. Thank you. I have wooden pallets! I do not have a welder - I'd like one!

I think I have set the points to 20 thou. We shall see, I guess. I unscrewed the bowl on the bottom of the carburettor and it seemed very clean, so I screwed it back on. I did not check the small filter that Keith referred to earlier. It appears to be easily damaged.

I have to reinstall the fly-wheel and the fuel tank. I shall then reconnect the fuel line.

I have bought neither gear-box oil nor two-stroke oil yet. I was hoping that somebody might have posted a source in Derbyshire, however no luck yet. I shall probably order them online this week.

Thanks for the help here.

Re: We have a Seagull Outboard

You don't need much more than a piece of wood in front of the thumb screws, like this.

Re: We have a Seagull Outboard

Thanks for that, Keith. Upon blowing up the photograph I can see what you mean. As you said about a wheelie bin, clamping to a square bin has to be easier!

Nice looking motor!

Mike

Nice looking motor!

Mike

Re: We have a Seagull Outboard

yes, it should have, I think it helps centre the cover, its pretty much the same as the old style set up, but in one piece of plastic.

My picture has a brass flywheel added, its not a seagull part.

My picture has a brass flywheel added, its not a seagull part.

Re: We have a Seagull Outboard

Well, I've ordered my oils and am looking for the washer that goes under the Domed Nut on top of the flywheel.

I've remounted the fuel tank, however I shan't connect the fuel line until I've washed out the tank with some fuel/oil mix - up until now, I've only used kerosine to wash out the tank.

I shall look at my test barrel and think about how to mount the engine.

I vaguely remember somebody talking here of taking the prop off before test running the Seagull in a barrel. Is this correct? If so, how do I remove the prop?

Thank you for the help.

I've remounted the fuel tank, however I shan't connect the fuel line until I've washed out the tank with some fuel/oil mix - up until now, I've only used kerosine to wash out the tank.

I shall look at my test barrel and think about how to mount the engine.

I vaguely remember somebody talking here of taking the prop off before test running the Seagull in a barrel. Is this correct? If so, how do I remove the prop?

Thank you for the help.