FVP10021

Moderators: John@sos, RickUK, charlesp, Charles uk

- Stelios_Rjk

- Posts: 1458

- Joined: Sun Jun 17, 2012 10:15 pm

- Location: Athens - Greece

Re: FVP10021

I will do the measurement for you the next days.

To do it now I will have to unscrew the head nuts etc... But I haven't add any silicone, I assemble it just not to lie around all the parts.

edit: Ooops posting the same time with Charlesp

To do it now I will have to unscrew the head nuts etc... But I haven't add any silicone, I assemble it just not to lie around all the parts.

edit: Ooops posting the same time with Charlesp

I love the 10600/145 turns!!!

- Charles uk

- Posts: 4977

- Joined: Wed Feb 27, 2008 4:38 pm

- Location: Maidenhead Berks UK

Re: FVP10021

Thanks Charles, measuring 1 does not a fact make, certainly after 60 years home maintance, but after 6 or 7 all about the same, 17 gauge mild steel sheet.

Make it idiot proof and someone will make a better idiot.

Re: FVP10021

As a side note, remember that there's no debate about using a 'suitable sealant' on these motors - British Seagull actually specified that one should be used, and later insisted that it should be Bostik 771. I have no idea what this stuff actually was, I only know that the 60-year-old examples I have dismantled have a generous amount of dark grey/brown stuff that's like hardened tar or bitumen. Bostik have never heard of the stuff.

The original service documents for these motors refer not to a 'head gasket' but rather to a 'cylinder head face plate.

They furthjer recommended that a newly built motor (among many other bits of specific advice) should be run and 'run-in' at full throttle, definitely cautioning against a gentle process. This was to ensure sufficient lubrication. They reckon half a minute (out of water if you like) would get an initial bedding in of the rings.

Naturally they were very keen to point out that the clench ring bolt that secures the drive shaft to the crankcase should be tight, and wired. They refer to this in the owner's handbook, too, it's obvious that a number of incautious sailors must have slackened the wrong ring, and lost the bottom half of their motor...

The original service documents for these motors refer not to a 'head gasket' but rather to a 'cylinder head face plate.

They furthjer recommended that a newly built motor (among many other bits of specific advice) should be run and 'run-in' at full throttle, definitely cautioning against a gentle process. This was to ensure sufficient lubrication. They reckon half a minute (out of water if you like) would get an initial bedding in of the rings.

Naturally they were very keen to point out that the clench ring bolt that secures the drive shaft to the crankcase should be tight, and wired. They refer to this in the owner's handbook, too, it's obvious that a number of incautious sailors must have slackened the wrong ring, and lost the bottom half of their motor...

Re: FVP10021

I've fitted a copper head gasket to an FV and a FVP, both were good fits and the engines ran well. I doubt fitting copper instead of steel will make corrosion worse, and the small difference in thickness will hardly bother a low tech engine such as a seagull.

I've also fitted a copper gasket to an early SJM that had a steel one from new. Amazingly it worked fine

I've also fitted a copper gasket to an early SJM that had a steel one from new. Amazingly it worked fine

Re: FVP10021

Well done Stelios,

I have real affection for the FV/FVP range, although for size and weight the FVs take some beating!

Due to a complete mess up at the platers I have a plated drive shaft tube of length 18 1/2". This length is I believe the LS/FVP length (?). My 16" FV tube has been lost by the platers. I need to continue my argument with the plater to find my 16" tube, but I don't think he will be able to. All I need now is an FV tube to plate - anybody got one? If i can find a 16" tube then my plated 18 1/2" tube might be useful to you?

With CharlesP's advice I am trying to collect data on these early F/FV/FVPs, and so Stelios I wii add your FVP10021 to the list.

I would be interested in what spec carb you have got in respect of whether it has the additional stop on top of the carb to limit the throttle slide opening. My (earlier) FVs have this feature, but I do not know whether FVPs have it. I also note that it doesn't have any engraving on the magneto cover.

Jeremy

I have real affection for the FV/FVP range, although for size and weight the FVs take some beating!

Due to a complete mess up at the platers I have a plated drive shaft tube of length 18 1/2". This length is I believe the LS/FVP length (?). My 16" FV tube has been lost by the platers. I need to continue my argument with the plater to find my 16" tube, but I don't think he will be able to. All I need now is an FV tube to plate - anybody got one? If i can find a 16" tube then my plated 18 1/2" tube might be useful to you?

With CharlesP's advice I am trying to collect data on these early F/FV/FVPs, and so Stelios I wii add your FVP10021 to the list.

I would be interested in what spec carb you have got in respect of whether it has the additional stop on top of the carb to limit the throttle slide opening. My (earlier) FVs have this feature, but I do not know whether FVPs have it. I also note that it doesn't have any engraving on the magneto cover.

Jeremy

- Collector Inspector

- Posts: 4202

- Joined: Sun Jun 29, 2008 4:32 am

- Location: Perth Western Australia

- Contact:

Re: FVP10021

If the gasket sealant used on my FVP is what Charles mentioned as Bostik 711 then I instantly likened the crispy black residue to what is now available as

Permatex® Form-A-Gasket® No. 1 Sealant when I pulled it apart.

Reliable paste-like gasket sealant/dressing/coating. Form-A-Gasket No. 1 sets quickly to a hard set and is recommended for rigid, permanent assemblies. Use to 400°F (204°C). Resistant to gasoline and other solvents. Conforms to MIL-S-45180 D.

Suggested applications: Coating cut gaskets to improve sealing and hold in place.

It is NOT Silicon

Still available at such as

http://www.permatex.com/

It used to be called Aviation Gasket 1 and Aviation Gasket 2. #1 was hard set and #2 was soft set. I have a little bottle of each still as a wee bit gos a long way. Applicator brush under the cap kind of thing.

Smells wonderful..................

and you will not go wrong in using it

Cheers

B

PS: 711 could be something like the old Shellac type sealants like Indian Head etc.

Permatex® Form-A-Gasket® No. 1 Sealant when I pulled it apart.

Reliable paste-like gasket sealant/dressing/coating. Form-A-Gasket No. 1 sets quickly to a hard set and is recommended for rigid, permanent assemblies. Use to 400°F (204°C). Resistant to gasoline and other solvents. Conforms to MIL-S-45180 D.

Suggested applications: Coating cut gaskets to improve sealing and hold in place.

It is NOT Silicon

Still available at such as

http://www.permatex.com/

It used to be called Aviation Gasket 1 and Aviation Gasket 2. #1 was hard set and #2 was soft set. I have a little bottle of each still as a wee bit gos a long way. Applicator brush under the cap kind of thing.

Smells wonderful..................

and you will not go wrong in using it

Cheers

B

PS: 711 could be something like the old Shellac type sealants like Indian Head etc.

A chicken is one egg's way of becoming others

- Stelios_Rjk

- Posts: 1458

- Joined: Sun Jun 17, 2012 10:15 pm

- Location: Athens - Greece

Re: FVP10021

Yeap, It does have the stop above the slide. And there is no engravings on the cover.

About the tube. Mine is 18 1/2". Why don't you just cut the existing? Of course after demolishing platters shop.

Hi Bruce,

I know it's not silicone but I didn't bother to find the correct word

I have found good results sealing gearbox cap with shellac by the way. I applied it on both surfaces and place the gasket between them.

About the tube. Mine is 18 1/2". Why don't you just cut the existing? Of course after demolishing platters shop.

Hi Bruce,

I know it's not silicone but I didn't bother to find the correct word

I have found good results sealing gearbox cap with shellac by the way. I applied it on both surfaces and place the gasket between them.

I love the 10600/145 turns!!!

- Collector Inspector

- Posts: 4202

- Joined: Sun Jun 29, 2008 4:32 am

- Location: Perth Western Australia

- Contact:

- Stelios_Rjk

- Posts: 1458

- Joined: Sun Jun 17, 2012 10:15 pm

- Location: Athens - Greece

Re: FVP10021

I was messing with the little forty, I managed to remove the ignition system and the cracked tiller arm. I decided to turn the flywheel to see if I could get something.

I get a spark on the points

I thought it should be a faulty condenser.

But there was no resistance measurement on the coil.

But since I saw a spark there is something alive inside there.

I replaced the condenser (thanks Kean ), clean and set again the points and the little girl did her miracle. I saw regular sparks HT lead to ground.

), clean and set again the points and the little girl did her miracle. I saw regular sparks HT lead to ground.

Obviously the winding of the coil is interrupted. At some point it will fail for good, but I think it's OK to leave it so as I won't use it in the sea.

I get a spark on the points

I thought it should be a faulty condenser.

But there was no resistance measurement on the coil.

But since I saw a spark there is something alive inside there.

I replaced the condenser (thanks Kean

Obviously the winding of the coil is interrupted. At some point it will fail for good, but I think it's OK to leave it so as I won't use it in the sea.

I love the 10600/145 turns!!!

- Collector Inspector

- Posts: 4202

- Joined: Sun Jun 29, 2008 4:32 am

- Location: Perth Western Australia

- Contact:

Re: FVP10021

"Yeap, It does have the stop above the slide"

It is not a "Stop"

It is a "Guide" that stabilizes 1/2 to open throttle for the slide. Early Villiers of all applications had this feature. Induction noise is minimized as rattle was taken out.

This Guide as above does not stop full travel in any way.

Those with this have a receiving hole in the slide ............ later ones do not. Have a squiz and compare.

Cheers

B

It is not a "Stop"

It is a "Guide" that stabilizes 1/2 to open throttle for the slide. Early Villiers of all applications had this feature. Induction noise is minimized as rattle was taken out.

This Guide as above does not stop full travel in any way.

Those with this have a receiving hole in the slide ............ later ones do not. Have a squiz and compare.

Cheers

B

A chicken is one egg's way of becoming others

Re: FVP10021

C.I. have a look again, between the cable and the guide, its only a short stop, I don't have it on my finished FVP, but I think I changed the carb on that one, goes a lot faster without it.

- Stelios_Rjk

- Posts: 1458

- Joined: Sun Jun 17, 2012 10:15 pm

- Location: Athens - Greece

Re: FVP10021

Hi guys,

Any tip to remove the gearbox cap? It seems pretty stuck.

Any tip to remove the gearbox cap? It seems pretty stuck.

I love the 10600/145 turns!!!

Re: FVP10021

Remove the prop, remove the brass bush and pin, put some steel in the prop spring slot to stop it closing up and tap the shaft through and that will push off the cap.

- Stelios_Rjk

- Posts: 1458

- Joined: Sun Jun 17, 2012 10:15 pm

- Location: Athens - Greece

Re: FVP10021

Great, thanks!!! That hadn't cross my mind. Unfortunately I have already removed the cap with heat and blade where the gasket sits. No great damages. Inside the there were some dinosaurs and an alligator... I will post pictures tomorrow.

I love the 10600/145 turns!!!

- Stelios_Rjk

- Posts: 1458

- Joined: Sun Jun 17, 2012 10:15 pm

- Location: Athens - Greece

Re: FVP10021

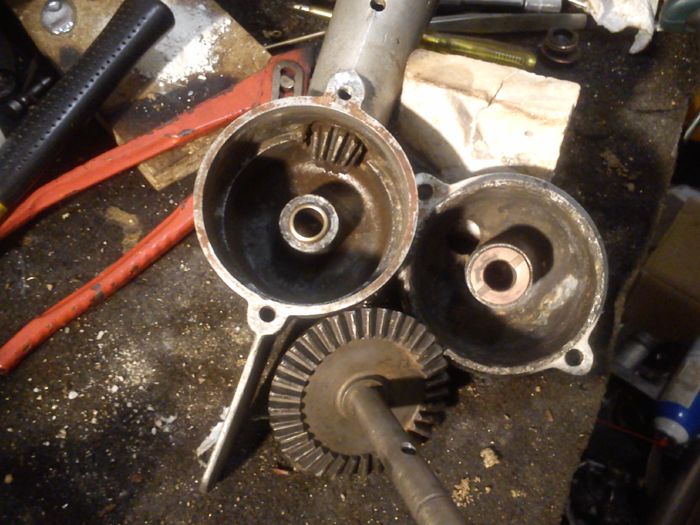

The part that gets in the main gearbox is longer than in later engines. The red stuff was a serious problem when dissembling.

And after cleaning.

Bevel pinion is a little bit damaged but still usable. Gearbox seems to be the most affected parts on this engine.

I love the 10600/145 turns!!!