Page 3 of 3

Re: 97cc Seagull

Posted: Sun Jan 14, 2018 10:25 pm

by NaughtyBits

The bodies for the pumped versions of the 400 series all have the appropriate tube drilled out to take the wider triangular-profiled fuel needle valves (brass viton tipped or white plastic) - is that right?

A search will bring up Charles’ old post from a few years ago, detailing all the BS Amal 400 versions (pumped & gravity fed), if I’m remembering it right. (EDIT: list was specific to QB range)

Re: 97cc Seagull

Posted: Sun Jan 14, 2018 11:03 pm

by Charles uk

I don't remember doing a post with all the details, I've slept since then.

I think your right Mr Bits, the 416/1 was available for both needles (small & large).

The 418 only with the needle retained by the float, small.

The 419 (SD110 Inboard) small for gravity, large for pumped.

The 420 I've only seen the pumped versions with large needles.

Re: 97cc Seagull

Posted: Wed Jan 17, 2018 9:52 pm

by GarethJ

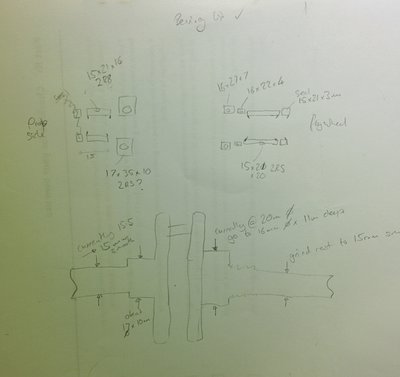

Following a nice chat with a forum member this morning, I riffled through some of the drawings I did and found the bearing details.

- Bearings

You can hopefully make out the layout. Two questionably dainty ball bearings on the upper end and a single medium sized one at the bottom. Flanked either end with a needle roller. For good measure there is an oil seal up top too. No room at the bottom

And the wrist pin

- "do not scale from drawing"

You can see I was going to use a caged roller an indeed tried this but it was all a bit flimsy so upgraded to longer crowded needles. Clearly the ends of the spacers there don't poke into the cylinder wall, in fact, they ended up quite a bit different so that I could ream the internal bore diameter to size easily but it gives the general idea.

Re: 97cc Seagull

Posted: Mon Jan 22, 2018 7:35 pm

by GarethJ

Managed a test on the pond with tachometer this afternoon. (A test on the pond just involves clamping the motor onto a jetty and seeing what it will rev to)

With a 2hp Yamaha prop, 7,1/4 x 4, It will do 5750 RPM. Some fluctuations above but I suspect cavitation

With a prop of unknown manufacturer, 8,1/4 x 8, it will do ~3300 RPM.

I also briefly tried it unloaded, a pretty nasty thing to do but nothing fell off or popped out the side. It maxes out (with this carb) at 7000-8000 RPM.

At the revs the small prop will achieve, there is some pretty hideous vibration. To the point where I doubt the petrol tank mounts would survive the abuse for long - the petcock already vibrates itself closed! The balance of the prop was way off (even as measured on a very heath robinson setup) so I've brought that into balance as close as I can measure but I feel the issue may well be more likely engine related. Or indeed the flywheel - unfortunately, the taper I machined has not resulted in a perfectly true flywheel.

Re: 97cc Seagull

Posted: Tue Jan 23, 2018 3:06 am

by NaughtyBits

Hopefully it's not too bad? That'd make me nervous..

I usually end up bending a narrow hose clamp piece into a 'question mark' shape (cut off the screw section) to pop over the open fuel tap. Tie it off on the fuel line with some whipping thread & then it's always there when you need it.

Re: 97cc Seagull

Posted: Wed Jan 24, 2018 12:34 am

by GarethJ

No, it's not too too bad. But bad enough. I put a clock on the flywheel lower lip the other day and it had about 15 thou of wibble.

Whoever removed the crank from the original motor must have duffed up the centre drilling on the end. I tried to get it true but must have been off a tad. Amplified by the 6"flywheel. It could be corrected if I remove the crank sometime.

Nice idea with the hose clamp bit, I ended up wrapping a bit of wire round it as a temporary solution.

Re: 97cc Seagull

Posted: Wed Mar 06, 2019 11:58 am

by Pinger

GarethJ wrote:IMG_20170721_174302.jpg

A couple of questions if I may....

What did you (and others) use as 'filler' in the above pic?

There seems to be quite a lot of space filled. I'm aware that the new crank has a slightly shorter stroke than the original (38 vs 40mm) but I cant see that the reduction of throw by 1mm creates such space. Is the crankcase overly roomy for the standard crank or is the new crank with one-piece rod so much more compact than the standard split rod set-up as to create the additional space?

TIA.

Re: 97cc Seagull

Posted: Wed Mar 06, 2019 2:08 pm

by Charles uk

I use Loctite 615 Hysol but machine within a couple of days, as after a week it gets so hard HSS tooling has a very short life.

Before you go too far, check your port timing is OK for your application.

Studying Jennings, Blair, Bell & Dixon can help.

Re: 97cc Seagull

Posted: Wed Mar 06, 2019 2:22 pm

by Pinger

Thanks Charles.

I'll check out the Loctite product - principally for its temp capability as it will end up being used close to exhaust ports (but not exposed directly to exhaust flow).

Plan has changed. No longer OP (available cylinders held in compression and, being subjected to rocking couples emanating from both ends rule them out in that context) but contemplating a 'square six' (two banks of three, two crank axes). So far, Stihl MS880 cylinders looking most promising but have a stroke of 43mm. Hence enquiring crankcase size.

Definitely keeping my eye on timing and stock (conservative) Stihl timings will be retained.

I use Blair and Jennings in specific port time area calcs (Jennings for method, Blair to correlate to BMEP) and have read Bell - but who is Dixon?